|

ISO 9001

NSW 3644

VIC 3644

Standards

Australia

|

PROJECTS:

HYUNDAI:

"Behind every success story"

Brownbuilt

Products Supplied:

Pallet

Racking

UnichannelŪ Shelving

Raised Storage Area

Light and Medium Duty RUT Shelving

|

With

an incredible growth of around 40% every year

making it the country's biggest car importer,

Hyundai knows all about success. And its parts

warehouse in the Sydney suburb of Auburn knows

the consequences of such success:

high demands on the available storage space.

When

the warehouse opened in the late 1980's, it was

assumed that certain areas would be adequate for

years. Instead, only months later, space was at a

premium.

"I

don't think anyone expected Hyundai would grow so

much. When we first started operating, we carried

around 3,500 lines. Now it's around 25,000,"

says Chris Priestley, Parts Operations Manager.

|

| Helping every

step of the way has been Brownbuilt. Originally

chosen for its storage solutions, Brownbuilt has

become an integral part of the warehouse's

operations. Planning

volume increase was virtually impossible and new

storage modules were created on an ad hoc basis

as the available space changed, so teamwork has

been essential.

We had to use

whatever space was available to accommodate such

high growth," says Mr. Priestley.

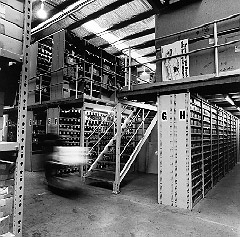

The warehouse is

divided into three units. Initially, one 2000mē

unit was used and as it was filled to capacity,

the second unit was taken bringing the floor

space to 2,900mē. Finally in 1994, the third

unit was used with the total space now around

4,700mē.

|

|

|

Obviously,

contingency plans were needed where possible.

Brownbuilt used medium-duty RUT shelving in one

area because there was a chance that a mezzanine

level would be required. It was, and this level

stores the parts for Jeep, which was added to the

distribution stable in 1994. Naturally, the range of

parts sizes and shapes is huge. From roof panels

to mufflers to nuts and bolts, everything must be

cleverly stored. Everything is kept in stacked

pallets or a small parts picking system.

Hyundai's 21 parts

warehouse staff pack and retrieve parts manually

and one aisle alone can hold 3,000 lines.

|

| Accessibility

is the key consideration, especially with quick

turnover from order to delivery (within hours for

the Sydney metropolitan area), and the pressure

to maintain the 93-95% first-pick supply to

dealers. The

need for accessibility in tight space

constraints, for example, led Brownbuilt to adapt

one of its standard shelving installations.

Specially made dividing rods help to accommodate

unusual shapes and make the best use of space.

Consistency of

product is very important when it comes to

storage, says Mr. Priestley. For that reason, the

warehouse is committed to using just one system -

Brownbuilt.

"We obviously

prefer a long-term relationship. It's easier to

deal with someone who knows the business and

knows what we're talking about. It's one

bandwagon and we're all on it", he says.

|

(Top of Page)

| Any questions

about our products and services can be directed

to (CONTACT) |

| Unichannel is a

registered trademark of Brownbuilt Pty Limited |

| Product

specifications are liable to change without

notice |

| This page and all

contents are copyright (C) by

Brownbuilt Pty Limited |

|